Flooding-Fighting Aids"Panic tends to rise with the water level but it’s important to remain thinking clearly ..."First ResponseFlooding as a result of a crash or a failing through-hull will demand immediate and concerted action of the complete crew. In this situation is very helpful if everyone on board is well aware of the elementary first steps to be organized:

A serious leak will have the sole boards awash in a few minutes. As time is crucial and tasks must be done in parallel, each crew member should know his precise role in this task list. Flooding CountermeasuresThis section will summarize some flooding-fighting measures that have been proven to work to a certain extent. Since each flooding scenario is different, it is worth to collect and absorb some different ideas to be able to come up with a practicable solution in a tangible case of emergency. Wooden Bungs This is a quick and easy to deploy solution if the leaking hole is perfectly round and not too wide.

This is usually the case if failing sealocks or other through-hull mounted hardware are

the problem.

After the bung has been put into the hole it will swell in the water, forming a good seal.

If the bung can be extra fixed to stay in position, this may be a practical more permanent

leak-stopping solution.

This is a quick and easy to deploy solution if the leaking hole is perfectly round and not too wide.

This is usually the case if failing sealocks or other through-hull mounted hardware are

the problem.

After the bung has been put into the hole it will swell in the water, forming a good seal.

If the bung can be extra fixed to stay in position, this may be a practical more permanent

leak-stopping solution.Bugs are available in a variety of sizes at low cost. They must be kept in a dry place in order to maintain the required swelling capability for securing a good seal. Cushions

A Cushion, a pillow, a blanket or even a towel may be stuffed into a larger hole

to temporarily reduce the intake of seawater.

These things are readily available in different sizes on almost any yacht and they

work reasonably for some time.

An appropriate plywood board may be used to keep the cushion firmly pressed against

the hull using your hands or feet.

Wrapping the cushion in a stable plastic bag before stuffing it into the leakage hole,

may improve the effectiveness of this method.

However, this method is unlikely to work for a longer time, but at least it can be

used to gain some time while trying to find a better way of sealing the hole.

Fothering, Leaksails or collision mats In nautical context, "fothering" refers to covering a leak in a ship with a sail

containing ropes to bring it in place at the outside of the hull and thus to prevent

the ship from sinking after being damaged.

This was the technique used to help to refloat Captain Cook's HMS Endeavour after

she went aground on the Great Barrier Reef on 11 June 1770.

In nautical context, "fothering" refers to covering a leak in a ship with a sail

containing ropes to bring it in place at the outside of the hull and thus to prevent

the ship from sinking after being damaged.

This was the technique used to help to refloat Captain Cook's HMS Endeavour after

she went aground on the Great Barrier Reef on 11 June 1770.For this technique principally any available (spare) sail can be used. Fixing the sail at the outside of the hull has the advantage, that the water pressure will push the sail firmly into the hole. But it is not simple to bring the sail in the correct position and even synthetic sails are not very watertight. As an alternative a special "leaksail" also referred to as "collision mat" can be prepared as part of the emergency hardware. This would consist of triangular shaped "sail" made of a strong, watertight fabric and supplied with long ropes at each of the corners. The actual size will depend on the size and hull form of the yacht. Since this type of covering may also be (mis)used as sunroof, maybe even two or three differently sized "leaksails" can be stored on board. More durable Sealing Solutions

The above ideas are primarily aiming at stopping the water from flowing uncontrolled into the boat.

But the final goal is to establish a more permanent and durable solution that must enable the yacht to be sail-able again.

Such a solution will depend on what is available on board to repair the hull and it will require a lot of improvisation

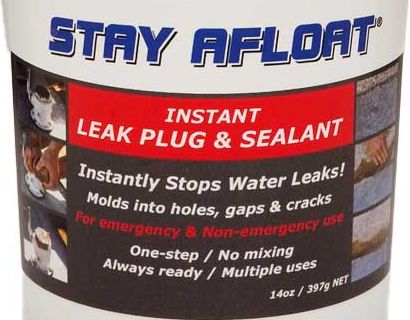

to install a solid repair that allows to reach a safe harbour. Stay Afloat Emergency Leak Sealant

Self-fusing Silicon Tape

Through-Hull FailuresBeside getting damaged by a crash situation, there are also some "home-made" issues that may lead to unwanted holes in the hull. Seacocks

Seacocks have three failure modes.

The most common is where a corroded pipe shears off at the hull, leaving nothing more than a hole.

The second is when the ball valve cracks, leaving just the through-hull fitting. Log and Echo SounderLog and echo sounder transducer fittings can fail, too.

Often the internal securing nut is mounted on a wooden pad.

If it’s not installed properly, the wood can get wet and swell,

shearing the nut off the thread, which means the fitting can fall out of the boat.

If the fitting is on a sharp turn of the bilge, the outer flange isn’t supported across

its full diameter and can crack.

When the flange breaks, the internal fitting is fired into the boat by the water pressure.

Another possibility is that the internal securing nut is overtightened,

which can also lead to cracking and a similar result. Sources1. Yachting Monthly, "Major Leaks!", October 2011, pp 84-94.2. Yachting Monthly, "Sinking!", September 2011, pp 32-40. |

| Cover << Sail Away << Safety Equipment << . | . >> Fire-Fighting Aids | last updated: 26-Sep-2020 |