Pulleys, Blocks and Tackles

Pulleys, blocks and Tackles are parts of different mechanical purchase systems,

which allow to multiply human pulling abilities in order to apply large forces

required to operate the heavy loads needed for trimming the rigg and sails on a

sailing vessel.

Pulleys and Blocks

|

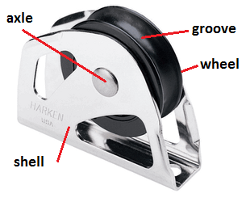

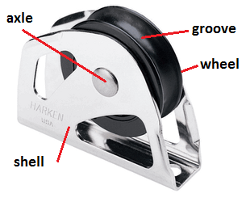

A pulley or block consists of a rotatable wheel or sheave mounted on a axle or shaft

and fitted in a supporting shell.

It is designed to support the movement (and change of direction) of a line or cable along

the wheel's circumference in order to change the direction of the pull.

A simple pulley can be used in a variety of ways to lift loads or to apply and transport forces.

The wheel normally has a groove or two flanges around its circumference to guarantee that

the line or cable will remain on the wheel and cannot get jammed between the wheel and the shell.

Pulleys are designed for use with a certain size of line or cable.

As a rule of the thumb the sheave diameter should be at least 7 times the line diameter.

Pulleys should especially not be used with lines of a larger size.

Lines under load, bent over a small sheave may be distorted and may result in rope wearing on the frame.

This will eventually result in a considerable reduction of the maximum applicable line load.

Typically, the term block is used for pulleys consisting of two or more sheaves as used in purchase systems.

|

|

|

On deck simple pulleys are used to keep lines away from the passages, where they would be a

potential tripping hazard. This usually implies that the lines must be lead out of the passage

way requiring a kind of guidance of the lines. Such pulley are called leading blocks

or turning blocks.

Another application of simple pulleys is guiding the halyards and sheets from the mast to the

cockpit for more comfortable operation.

But it has to be taken into account that additional guidance also introduces additional friction.

This eventually will require higher loads for operating the sheets and halyards.

|

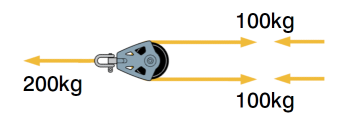

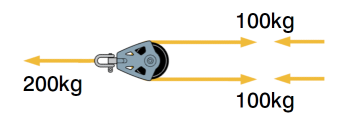

Forces working on the mounting gear of pulleys

In the extreme case in which the direction of the load is turned over 180°, the force on the

pulley's axle and mounting gear will be twice the applied load on the line:

|

The Block load "F_block" may be calculated from the line load "F_load" and the deflection angle "d" as follows:

F_block = F_line * 2 * cos(d/2)

A 90° deflection still results in a block load, which is 40% higher than the line load.

|

An example of how the deflection angle changes the resulting load on the suspension of

the block, is the tow load required to fix the genoa cars: depending on the size of the genoa,

a typical deflection angle at the genoa car block is between 40° (full-size genoa)

to 70° (reefed genoa or jib). The corresponding load on the tow line of the car, will be in the

range 25% to 65% of the sheet load.

Depending on how the pulley is mechanically fixed, also the direction of the resulting working

force may be important.

This is the case e.g. if the mounting plate of the block is screwed on the deck structure or fixed on a rail

(e.g. genoa cars or main sheet travellers).

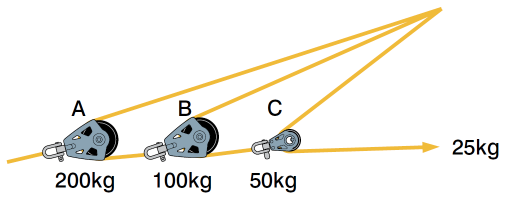

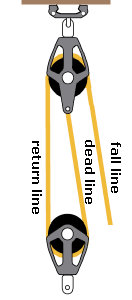

Blocks-and-Tackles

|

A set of pulleys can be assembled to a blocks-and-tackle system, which provides mechanical advantage

in a so called purchase system and can be used to apply large forces.

Each tackle system contains a fixed block attached to to some solid support and may

have a travelling block attached to the load.

|

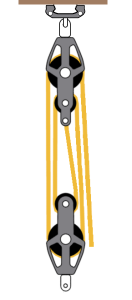

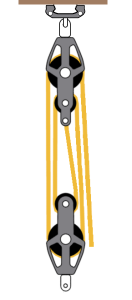

Multi-purchase systems

A multi-purchase system basically consists of two blocks connected with a single multi-looped line.

This setup is used where the full range of adjustment - between the basic blocks - is required.

This means that all pulleys travel the same range (in contrast to cascaded blocks - see below).

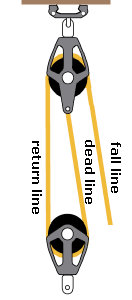

The simplest multi-purchase system is shown on the right.

This system, known as "gun tackle", has a purchase factor of two and consists of two single-sheave blocks.

The upper (fixed) block is called "standing block" and the lower block is called "travelling block".

Notice that the load on the upper mounting is three times the line load.

If the fall line is pulled with 50kg, a load of 100kg can be lifted, but the upper fixation will see

both the 50kg line load plus the 100kg load on the lower fixation.

On the left a 1:4 purchase system is shown.

Instead of parallel sheaves in a common axle, here, the sheaves are placed above each other on individual axles.

By using sheaves of different sizes, the line friction can be reduced in this system.

The blocks used in this setup are called "fiddle blocks".

|

|

On the efficiency of purchase systems: A certain amount of the force applied to a

tackle is lost through friction. As a rule of the thumb each 180° turn in the blocks

will reduce the efficiency of the purchase system by 5%.

So a 1:4 purchase system will have an efficiency loss of 15 to 20%.

In this case, the line load for lifting a 100kg load will be rather 30kg instead of 25kg.

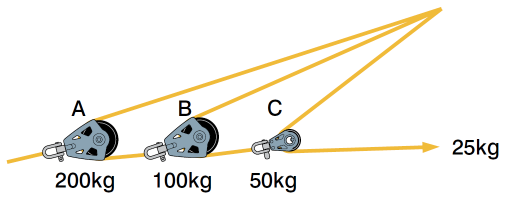

cascaded blocks

An alternative way to build mechanical purchase systems is the cascading of blocks:

The advantage of the cascade arrangement is that for a certain purchase factor less blocks

are required and that lines and sheaves can be selected in line with the load on each

part of the system.

The disadvantage is that this system is slightly more complicated and achieves a smaller

range of adjustment.

Each block in the system requires sufficient travel range.

Block B travels twice the distance and block C four times the distance of Block A

(hence the smaller adjustment range).

For a proper working system, all blocks must be free to travel their full working length

without danger of getting stuck.

|