Winches

|

Winches are mechanical devices, which consist of a rotatable drum that carries a loaded line.

The drum is rotated manually with a hand crank or electrically with a motor.

This driving force is put on the drum through an integrated gear mechanism.

Winches use the principle of levers to increase force and torque.

Modern winches use two types of lever principals: one internal, the other external.

The external lever is the lever arm or the winch handle and the internal lever

is the integrated gear reduction consisting of revolving sets of gear wheels.

The combination of these two effects results in a power ratio, the theoretical

mechanical advantage of the winch. |

|

Self-Tailing Winches

|

Self-tailing winches have a line stripper and a spring loaded disk that acts as a jam cleat

on top of the drum. The self-tailing mechanism is designed to strip the non-loaded end of

the line from the drum and to hold this part such that the line will not slip on the

drum while the winch is operated.

Self-tailing winches allow to have both hands free for grinding.

Today, almost all installed winches on sailing yachts are self-tailing winches.

All self-tailing winches use some kind of mechanical brake or ratchets principle to prevent the

drum from rotating in the wrong way if the driving load of the winch is removed.

This means these wiches can be used to pull in the line under load but they have no

direct arrangement to slacken the line. |

|

|

In order to slacken the line, the "low-load" end has to removed from the self-tailing cleat

and - while keeping sufficient load on the line - let it slip over the winch drum

using the friction of the 3-4 turns on the drum to control the slackening.

This procedure is a potential hazard: the load on the line my be to high to control

the slackening with the danger of the line pulling the operators hand and fingers

onto the winch.

|

Power Ratio

The power ratio of a winch is the term used to describe the ability of winches to pull

a certain load by applying a considerably smaller force on the winch handle.

Many manufacturers (e.g. Harken, Lewmar, ...) use the winch's power ratio

(under certain conditions) as the winch model name.

In this case for example, a "48-winch" has a power ratio of 48:1 in the final

gear using a standard 250-mm (10") winch handle.

This means a kilo of handle input will generate 48 kilos of load power.

A normal adult is able to pull loads of 15-20 kg so through an 48-winch

he is capable to apply 700-950 kg of load on sheets and halyards.

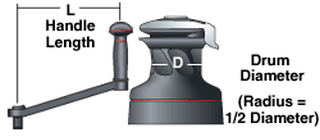

Technically, the power ratio is calculated as:

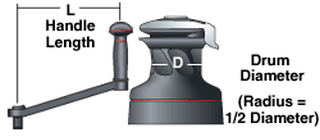

Power_Ratio = (Handle_Length / Drum_Radius) x Gear_Ratio

|

The standard handle length is 250 mm (10"). Shorter handles, which are

used for faster winch speed are usually 200 mm (8"). Drum radius can be measured or found from the specifications. Gear ratio can be determined from the winch specifications or it can be

obtained by counting the number of handle rotations needed to rotate the drum over

one full turn. |

However, the power ratio may be considerably reduced by friction in the winch and in the lead blocks.

Every change of direction that the line put on the winch makes causes friction and will reduce

the efficiency of the equipment.

This might have to be considered while planning the placement of the different winches on deck.

Winch Speed and Winch Load

The "speed" of a winch, is the amount of line that is pulled for

each revolution of the handle. The primary considerations in determining winch

speed are the gear ratio and the drum circumference. Since the line is wrapped on

the drum, each revolution of the winch will pull in an amount of line equal to the

circumference of the drum (circumference = π x diameter).

The "load" a winch can generate is the force it can apply on the attached line

with a certain amount of force on the winch handle.

This is related to the power ratio of the winch.

Since a winch is a passive device, the mechanical power it delivers on

sheets and halyards (which is equal to winch speed times winch load),

must be supplied by the human operator and this power is limited:

Winch_Power = Winch_Speed x Winch_Load

|

|

If the available power is constant, winch speed and winch load are inversely related.

This is simply due to the energy-conservation principle of mechanical machines.

|

|

Fast trimming can only be obtained with lower loads and high loads will imply slow trimming.

This is the reason that all moderate and large winches are offered with two or three speeds.

For light loads, the fast speed gear can be used that doesn't offer much load,

and as the load increases, you can shift to the lower speed gear and trim the last

part at higher load.

A simple way to increase the speed of a winch is to use a shorter handle, typically

a 200-mm (8") handle. The 8" handle is faster because it swings in a smaller arc

and can be rotated faster.

The same power problem is experienced, though, as handle length is a

part of the power-ratio calculation and decreasing the handle length by 20%

also reduces winch load by 20%. Still, the 8" handle is a very effective and inexpensive

means of increasing winch speed in light and moderate conditions.

|

Faster trimming can also be obtained by using a wide-body winch with a

large diameter drum. Unfortunately, since the drum diameter is also a function

of the power ratio, the wide-body winch will offer less power for the same gear ratio.

Faster winch speeds can also be achieved with three-and four-speed winches.

A typical smaller three-speed winch, offers direct drive in first speed.

The drum turns one revolution for each revolution of the handle, so under

low loads, sheets can be trimmed very fast.

While this speed is not geared, there is only the slight mechanical advantage

obtained from the relationship between the lever (handle) and the drum diameter.

Larger three-speed winches, typically have a geared first speed because for these

winch sizes, even under low loads, some additional mechanical advantage is required.

|

Line Alignment

Winches are further affected by how they are mounted on the boat.

The most important factor is to ensure a proper line entry angle.

Lines must lead up to a winch at about a 5- to 10-degree angle to obtain

correct winding and to prevent overrides of the sheet on the drum.

Lead blocks should be positioned in an appropriate way to ensure this

optimal entry angle up to the drum.

Alternatively, the winch must be raised or lowered slightly.

|

|

|

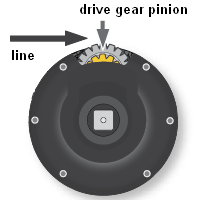

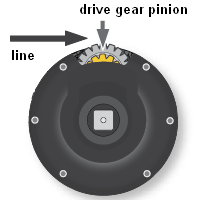

It is also important to mount the winch such that the loaded line is

properly aligned to the position of the final drive gear pinion.

This must be considered during the installation of the winch and it

is important to know on which side (internal) the drum pinion is located.

This position is normally marked on the the drilling cut-out template

available from the manufacturer.

The winch must be mounted on the deck so that

the drum pinion is positioned on the same side at which the sheet enters

and loads the winch drum.

Improper alignment will dramatically increases the load on the gear

housing resulting in inefficient operations, and in severe cases,

in winch failure.

|

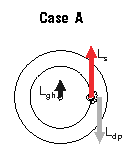

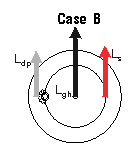

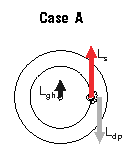

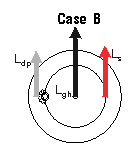

Ls=Sheet Load; Lgh=Gearing Housing Load; Ldp=Drive Pinion Load

|

|

On the left two extreme examples are shown:

one with the load aligned properly and one with the opposite situation.

In case A, with the proper alignment, the load on the gear housing is minimized since

Ls and Ldp are in opposite directions. In case B, where the load is improperly

aligned, the load on the drive gear is maximized: in this case the loads are

in the same direction and adding up.

Notice that the forces exercised on the deck are independent of this and consist of

the line load (Ls) and a torque equal to line load times drum diameter

(M = Ls x Ddrum).

These forces must be delivered by the bolts connecting the winch to the deck. |

|