Wind Generators

Wind consists of moving air masses and is a form of solar energy.

Uneven heating of the atmosphere by the sun forces air masses to flow

from colder to hotter regions.

A wind turbine can convert the kinetic energy of the wind into

mechanical power, which can in turn drive an electrical generator.

The main advantage of wind generators is that it consists of robust, reliable

and cheap technology.

Basic Principles of Wind Generators

Wind generators used on leisure sailing yachts consists of a wind turbine

rotating on a horizontal axis which is directly connected to an electrical

alternator.

This system is mounted on a special mast or post, such that the body of the

generator can turn freely on a vertical axis.

This way, the orientation of the rotator front can be adapted optimally to

the veering winds.

Wind generators used on leisure sailing yachts consists of a wind turbine

rotating on a horizontal axis which is directly connected to an electrical

alternator.

This system is mounted on a special mast or post, such that the body of the

generator can turn freely on a vertical axis.

This way, the orientation of the rotator front can be adapted optimally to

the veering winds.

The rotor must be constructed such that is capable of converting as much of the

kinetic wind energy as possible into mechanical power to drive the alternator.

This optimization can only be achieved for a small range of wind speeds.

Optimizations for larger wind ranges will require pitch adaption of the

rotator blades, which will increase the cost and decrease the robustness

of the wind turbine.

But even when the wind generator has pitch adaptable rotor blades,

the rotor will still have only a limited range of wind speeds in which

it will show optimal performance.

Also the alternator will have to be optimized for this nominal

rotator speed since both are mounted on the same axis without

intermediate gearbox.

The optimal rotation speed has a direct impact on the design of the

rotor: rotors optimized for a lower rotation speed have more

rotor blades than rotators optimized for high rotation speeds.

The rotors used in modern marine wind turbines typically have three,

five or six rotor blades.

The rotor converts the wind power into mechanical power, which is used

to drive an electrical generator.

The generator is usually an alternator, which produces alternating current (AC).

It consists of a rotating multi-pole magnetic rotor and multiple fixed stator coils.

The rotating - alternating - magnetic field will induce an alternating

voltage in the stator coils mounted around the rotator.

By choosing an appropriate parallel-series connection of the stator coils,

the desired nominal generator output voltage can be obtained.

For loading batteries, the alternating current generated by the alternator

has to be converted to a direct current (DC) by means of semiconductor rectifiers.

The rectifier is integrated in the generator and although semiconductor

rectifiers are very reliable and robust, the main drawback of this setup

that the diodes in the bridge-rectifier have a voltage drop of about 1.4V,

which is about 10% of the generated voltage.

So this voltage drop results in a 10% power loss!

Performance of Wind Generators

|

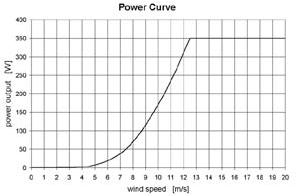

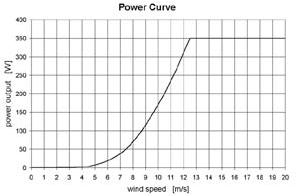

Basically the power that can be generated with a wind generator

(Pgen) depends on the wind speed (vwind)

and the area covered by the rotor (Arotor).

Pgen ~ v3wind * Arotor

This is illustrated in the graph on the right:

in the wind speed range of 4 to 12 m/s, the cubical relationship between wind speed

and output power is apparent.

Above 12 m/s (24 knots) wind speed, the output power is limited by the

maximum rotation speed of the rotator.

The rotation speed has to be limited to avoid physical damage of the rotator blades

due to the centrifugal forces, which increase quadratically with the rotation speed.

|

|

|

Note that not all generators have this overspeed protection as an automated

feature and some models may require manual action to prevent damage of the generator

components.

Such units should not be left unattended when extreme wind conditions are

expected.

|

Practical Implementations

The table below shows the power output for some commercial marine wind turbines.

These are optimized for wind speeds in the range 4 to 6 Bft.

Different techniques are used for maximum rotation speed protection.

Some implementations have an electronic rotation speed control,

which will shunt the generator at high wind speeds.

By shortening the stator coils, the generator will work as a very effective

eddy-current brake for the rotator.

Other vendors use a mechanical brake system that is activated by the centrifugal

forces acting on the rotor blades.

This principle is more reliable, since it does not rely on electronic control

circuits.

Examples:

Vendor - Model |

Rotor

Area |

Number of

Rotor Blades |

Approx.

Weight |

P @ 5m/s

(10Kn / 3Bft) |

P @ 10m/s

(20Kn / 5Bft) |

P @ 15m/s

(30Kn / 7Bft) |

| Ampair - 100 |

0.8 sqm |

6 |

9 Kg |

12 W |

70 W |

100 W |

| Ampair - 300 |

1.1 sqm |

3 |

12 Kg |

20 W |

150 W |

320 W |

| LVM - Aero4gen |

0.6 sqm |

6 |

9 Kg |

15 W |

75 W |

140 W |

| LVM - Aero6gen |

1.2 sqm |

6 |

15 Kg |

30 W |

120 W |

240 W |

| Rutland - WG503 |

0.2 sqm |

6 |

4 Kg |

6 W |

20 W |

50 W |

| Rutland - WG913 |

0.7 sqm |

6 |

10 Kg |

20 W |

40 W |

140 W |

| Eclectic Energy - D400 |

1.0 sqm |

5 |

15 Kg |

40 W |

200 W |

350 W |

| Superwind - 350 |

1.1 sqm |

3 |

12 Kg |

12 W |

180 W |

*) 350 W |

*) The generator is in overspeed-protection mode

The power consumption on board of a vessel highly depends on the installed equipment

(refrigerator, watermaker, lights, pumps, transmitter, ...)

and the general "lifestyle" of the crew concerning comfort requirements.

But as an average value, the daily power requirement may be estimated to 1200 Wh/day.

This would require a wind generator providing e.g. 100W over 12 hours per day.

From the table above, it can be seen that with an average wind of 3 Bft over 24 hours,

is not possible to generate this amount of energy!

So a combination with solar panels may be necessary to cover the required

energy consumption.

Service and Installation

The service intervals for marine wind generators are between 7 and 10 years.

Typical parts that have to be replaced in these intervals are the rotor blades and

the rotor bearings.

When mounting on a yacht or boat, positioning the turbine will be influenced by

the configuration of the boat and other equipment fitted. It is important to ensure

that the blades are at sufficient height such that injury to the crew from rotating

blades is unlikely.

It must also be ensured that under no circumstances, any part of the turbine can come

into contact with parts of the boat's fittings or rigging.

In addition to wind loads, the turbine is subject to dynamic loads when the yacht is

in a seaway. Therefore, the tower should be appropriately supported and securely braced.

A controversial topic is the noise and vibrations produced by wind turbines on

modern fiberglass yachts.

Noise is produced in the first place by the wind soughing through the rotator blades,

but this is pretty much comparable to the noise the wind generates in the rigg.

But additionally, the vibrations of the rotating alternator are directly

transferred to the mounting of the generator and further to the hull of the yacht.

The hull acts as an acoustical amplifier and will eventually transfer the

vibrations to the surrounding water.

While under sails, this is not really a problem since the wind and the water rushing

will drown most of the noise on board.

But when moored, the vibrations may be very annoying.

So, if feasible, the wind generator installation should include marine-proof

anti-vibration mounts under the main tower and bracing struts.

|

Wind generators used on leisure sailing yachts consists of a wind turbine

rotating on a horizontal axis which is directly connected to an electrical

alternator.

This system is mounted on a special mast or post, such that the body of the

generator can turn freely on a vertical axis.

This way, the orientation of the rotator front can be adapted optimally to

the veering winds.

Wind generators used on leisure sailing yachts consists of a wind turbine

rotating on a horizontal axis which is directly connected to an electrical

alternator.

This system is mounted on a special mast or post, such that the body of the

generator can turn freely on a vertical axis.

This way, the orientation of the rotator front can be adapted optimally to

the veering winds.