Ropes

Introduction

Rope is the generic term for cordage of over 8mm in diameter,

while thinner stuff is known as cord, twine, line or string.

Finer still is thread and double yarn.

Rope is commonly used to describe bulk material, such as a spool of rope at the

chandlery, while line is generally defined as rope cut from such a spool and used

for a specific task on board (e.g. a sheet or a spring line).

In this section, both the terms rope and line as used interchangeable.

Despite the large variation of polysyllabic names that rope manufacturers use

to describe their products, selecting the right rope depends on three things:

material, method of construction and application (what is the rope used for).

Rope Material

The vast majority of lines found on-board today are made of synthetic fibres like

polyamid, polyester and polypropylene, compared to 40 years

ago when organic materials such as hemp, sisal and cotton were used.

Synthetic lines have numerous advantages over their organic counterparts,

not the least of which are increased strength and resistance to rot.

The large variety of synthetic lines also allows boaters to better find

a suited line for a specific application.

But despite the large variety of high-tech rope materials available today,

the three basic materials remain polyamid, polyester and polypropylene.

Polyamid's strength, excellent abrasion resistance, and good elasticity make it

an ideal choice for applications involving shock loads, such as anchor and dock lines.

The high elasticity, however, makes it unsuitable for halyards and other uses

where little stretching is required.

Polyamid is also susceptible to water absorption, which may reduce the strength

by up to 15%

Polyester combines the desirable characteristics of strength and minimal

stretch, making it a good all-around line suited for most purposes on board. It

also has good abrasion resistance, doesn't shrink when wet, and maintains

flexibility in high temperatures. Purchased pre-stretched, it's ideally suited

for halyards, sheets and control lines on sail boats.

Polypropylene is the lightest but has the lowest strength of the three basic materials.

It's inexpensive and it floats, making it the rope of choice for dingy painters, ski tow ropes,

mooring pennants, and other applications where a submerged line might snag in your propeller.

Downsides include less strength than polyamid or polyester and susceptibility to UV degradation.

It also tends to melt under high friction.

The table below summarizes the most important characteristics for the three basic materials

and also for two so called high-tech materials High-Modulus Polyethylene and Aramid.

| | Polyamid

| Polyester

| Polypropylene

| High-Modulus

Polyethylene | Aramid

|

| Brand Names | Nylon | | | Spectra, Dyneema | Kevlar, Technora |

| Tensile Strength | high | medium | medium | high | high |

| Elasticity | high | medium | medium | low | low |

| Abrasion Resistance | very good | very good | fair | very good | good |

| UV Resistance | good | very good | fair | good | poor |

| Water Absorption | high | medium | low | very low | low |

Since the early 1950s, the chemical industry has spend a lot of development efforts on

fibre materials based on ultra-long-chain polymer molecules.

The longer chains serve to transfer load more efficiently to the polymer backbone by

strengthening the intermolecular interactions.

These developments were eventually commercialized in today's high-tech fibres with

extremely good high-strength, low-stretch and low-weight characteristics.

The overall benefit of high-modulus polyethylene (HMPE) or Aramid lines is that it takes a

much smaller line to achieve the same strength, saving weight not only in lines themselves,

but also in the gear like blocks and winches needed to control them.

HMPE or Aramid lines have a strength-to-weight ratio that is ten times better than

that of steel cables, yet the density is low enough to make them float in water.

HMPE is a strong, lightweight, low-stretch material good for running rigging as well as running

backstays and other applications where light weight and low stretch are

critical. It also resists weather and abrasion, doesn't soak up water and

doesn't shrink. The downside is that it's very slippery, and the core is subject

to creeping under sustained loading (meaning it will slowly stretch without

returning to its original length).

In addition to their high strength, Aramid fibres possess minimal stretch and

low creep characteristics.

Downsides include poor UV resistance and susceptibility to abrasion,

particularly when they're subjected to high bending loads as in blocks or

cleats, making them best for applications such as standing rigging.

Though polyamid, polyester and polypropylene still serve the average boater well,

there are places where these newer (and more expensive) high-tech lines can become

of interest, even for cruising boats.

For any application where lines should resist stretching - for example halyards or reef lines

- Aramid or HMPE materials may be considered.

Compared to organic lines, synthetic lines have some quirks such as creeping,

and extreme slipperiness. Some of these peculiarities cause especially high-tech lines

to perform radically different under otherwise familiar situations.

Knots are a good example for this. Knots that have served sailors well for centuries

can severely damage high-modulus line to the point of early failure.

Knots weaken all ropes because they distort the fibres.

A bowline, for example, reduces the strength of polyester or polyamid line by as much as 40 percent.

This same bowline can reduce a high-modulus line's strength by 70 percent or more,

leaving little or no safety margin.

This means that all termination points in high-modulus lines should either be

splices or special end fittings instead of knots.

Rope Construction

Basic construction for synthetic and organic ropes begins with fibres,

which are twisted into yarns, then twisted or plied into strands, and finally

twisted or braided into rope. It's that last step that determines how the fibres

lay or align with the finished line and thus defines the properties of the line

itself.

Twisted or Laid Rope

Twisted rope is historically the prevalent form of rope, even today.

Common twisted rope generally consists of three strands and is normally right-laid, or given

a final right-handed twist (also called Z-twist).

Despite the improvements made by modern technology in manufacturing twisted rope,

it remains inferior to braided rope when used under certain conditions.

The advantages are simple spliceability, low price and well-grooved surfaces with

a good grip.

Curiously enough, natural fibre rope, once the only available everywhere,

is now often more expensive than synthetic fibre rope because there's simply not

as much of it made these days.

In a twisted or laid rope such as three-strand (the traditional

form of manufacture since the early days of natural rope), fibres are not

aligned with the line's axis, so the line will have more stretch than braided

or parallel core since the fibres straighten out as the rope comes under tension.

Twisted ropes have a preferred direction for coiling. Normal right-laid rope should

be coiled clockwise, to prevent kinking. Coiling this way impacts a twist to the rope.

Twisted rope must be bound by its ends by some means to prevent unravelling.

Braided Rope

Modern braided rope consists of a braided (tubular) jacket over strands of fibre.

It has more fibre in the line's cross section, translating to less stretch

and consequently greater strength.

Braided rope is torque-free, has good abrasion resistance, and is less

susceptible to kinking than traditional laid rope.

Single-braid rope is the simplest and most prevalent type of braided rope,

however other common types include balanced double-braided (a braided cover over

a braided core of the same material), core-loaded double-braid (braided cover

over a braided, lower-stretch core of different material), and parallel core (a

braided cover surrounding a bundled core oriented parallel to the line's axis).

Plaited Rope

|

Plaited rope is made by braiding twisted strands, and is also called square braid.

It combines high-strength and good shock absorption properties, which make it useful for mooring and tugging lines.

Its torque-free braided construction provides easy handling and prevents kinks. |

|

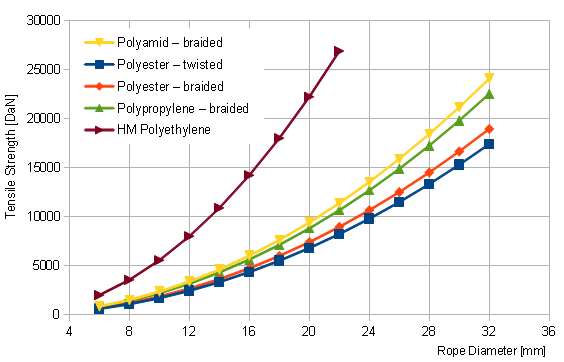

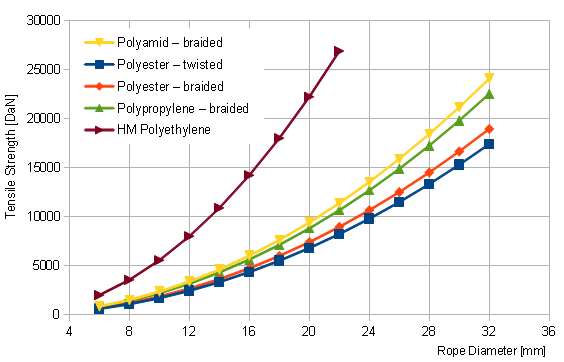

Rope Tensile Strength

Basically, the strength of rope is proportional to the

cross-section area of the rope or quadratically proportional to the diameter.

For some examples, the expected tensile strength as a function of the rope diameter is shown below:

However, rope strength itself is only part of the story. Any rope mend for

practical use, will have to be attached to some objects while under load.

Knots, bends or any curvation in the rope will reduce the resulting rope strength.

Also temperature, humidity and other environmental factors as well as wearing and ageing

effects will eventually affect rope strength.

Therefore, the safe working load of rope is rated at about only 20% of the tensile strength.

And this is valid only for static loads. If the rope is subject to dynamic loads, the

safe working load may be even lower than 5% of the tensile strength.

This depends on the dynamic parameters of the load.

Rope Care

Eventually, reliability and operability of ropes on board are a safety issue.

So some attention to maintenance and care should be given.

Chafe remains by far the worst enemy of any rope.

A regular inspection for burrs or sharp edges on the deck components such as

blocks, guides, chocks, cleats, windlasses, etc., is required.

All cotter pins and split rings in turnbuckles and blocks should be taped

using rigging tape.

Dirt and salt, can cause excessive wear and premature failure.

So if possible, rope and running rigging should be washed frequently with fresh water.

For this, the lines are soaked in warm water with a mild detergent and a little softener

to make them nice and soft.

After washing, the ropes must be rinsed thoroughly with clean fresh water to remove

the detergent before they are hanged to dry.

Wet rope should be thoroughly dried before it is coiled and stored or put into a bag.

Although synthetic fibres have pretty good chemical resistance, exposure to

harsh chemicals such as acids and alkalis should be avoided whenever possible.

The same is true of sunlight, as UV radiation degrades all fibres over time.

Cover or remove lines and bag or store them below decks where possible.

As for line handling, always begin coiling a line at the end that is made fast,

which allows any twists or kinks to be removed at the loose end.

Most laid ropes are right-handed (Z-twist), so coils should be counter clockwise to ensure

that lines play out smoothly.

Placing a kinked line under load weakens and damages it, often resulting in hard

spots caused by excessive friction heat that can literally fuse filaments together.

Applications

For the use on board there are typically only a few distinguishable applications.

General requirements on the applied rope are high strength and high durability.

But beyond that, each application has some specific requirements resulting

eventually in the need for different rope materials:

| Application | Basic Requirements | Suitable Rope Material |

| Standing Rigging | low weight, low stretch, low creep, UV resistance | HM-Polyethylene |

| Running Rigging | low weight, low stretch | braided polyamid |

| Mooring | high elasticity, rot and UV resistance | stranded polyester or polyamid |

Low-cost stranded steel cables are well established for setting up the standing rigging on pleasure sailing yachts.

HM-Polyethylene fibers such as Spectra or Dyneema are a low-weight alternative

with their low-creep and good UV resistance properties. Drawbacks are the higher cost and more complex handling.

Rope for running rigging such as sheets and halyards, should preferably have high-strength and low-stretch properties.

It has to stand continuous mistreatment in rope clutches, jam cleats or self-tailing winches, so high durability

is an important feature. For halyards, low creep is important to prevent continuous re-trimming of

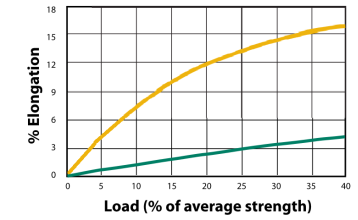

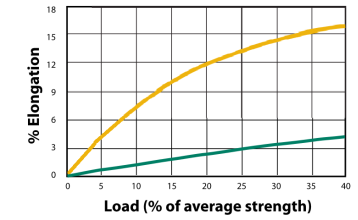

halyard tension. Typical stretch behaviour for running rigging rope is shown on the right (green).

Rope for running rigging such as sheets and halyards, should preferably have high-strength and low-stretch properties.

It has to stand continuous mistreatment in rope clutches, jam cleats or self-tailing winches, so high durability

is an important feature. For halyards, low creep is important to prevent continuous re-trimming of

halyard tension. Typical stretch behaviour for running rigging rope is shown on the right (green).

Dock lines on the other hand, should feature high strength, high elasticity and also a high UV and rot resistance.

For appropriate shock absorption, these lines should show a significant elongation under load.

Typically dock lines have about 15% of elongation at the maximum working load (yellow graph).

The elongation under load, effectively dissipates the surging energy of the moored vessel.

Stranded lines are preferred for mooring, because the twisted structure considerably

supports the required elasticity.

The recommended size for dock lines depends on the size and windage of the vessel.

Typical line size for a 40 feet yacht is 16mm (5/8") diameter.

If the vessel is subjected to surge while docked, a lager size is recommended.

Some Rope Manufacturers

|

Rope for running rigging such as sheets and halyards, should preferably have high-strength and low-stretch properties.

It has to stand continuous mistreatment in rope clutches, jam cleats or self-tailing winches, so high durability

is an important feature. For halyards, low creep is important to prevent continuous re-trimming of

halyard tension. Typical stretch behaviour for running rigging rope is shown on the right (green).

Rope for running rigging such as sheets and halyards, should preferably have high-strength and low-stretch properties.

It has to stand continuous mistreatment in rope clutches, jam cleats or self-tailing winches, so high durability

is an important feature. For halyards, low creep is important to prevent continuous re-trimming of

halyard tension. Typical stretch behaviour for running rigging rope is shown on the right (green).