Estimation and Installation of the required Battery Capacity

The electrical power supply on board of small sailing vessels should be planned

carefully in advance of it's installation.

Later changes especially capacity enhancements will often result in serious

installation and reliability problems.

Estimating the Energy Requirements

To plan the battery capacity to be installed, the supply requirements have to

be estimated for different situations.

On a 3-week transatlantic journey, the electrical supply requirements will be

different from the requirements during a 3-week anchoring period.

During anchoring the auto-pilot or GPS receiver will not be used, whereas

under sails, the required energy for the cabin lights may be lower, depending

on how the crew is spending their "off-guard" and "stand-by" periods.

The following scheme should be elaborated for each different situation

(journey under sails, anchoring periods, ...) to determine the worst case daily

energy requirements:

| Electrical Loads |

|---|

Device

|

Power

[W] |

Current

[A]@12V |

Operation

[h/day] |

Energy

[Ah/day] |

|---|

| Refrigerator |

120.0 |

10.0 |

6.0 |

60.0 |

| Autopilot |

24.0 |

2.0 |

18.0 |

36.0 |

| Position Lights |

60.0 |

5.0 |

6.0 |

30.0 |

| Cabin Lights |

120.0 |

10.0 |

2.0 |

20.0 |

| Radar / Plotter |

60.0 |

5.0 |

3.0 |

15.0 |

| GPS receiver |

2.4 |

0.2 |

24.0 |

4.8 |

| Radio TX |

360.0 |

30.0 |

0.5 |

15.0 |

| Water Maker |

60.0 |

5.0 |

4.0 |

20.0 |

| Water Pump |

60.0 |

5.0 |

0.5 |

2.5 |

| Anchor Winch |

1200.0 |

100.0 |

0.2 |

20.0 |

| ... |

... |

... |

... |

... |

| Drained Energy |

- |

- |

- |

250.0 |

| Electrical Generators |

|---|

| Solar Pannels |

96 |

8 |

6.0 |

48.0 |

| Wind Generator |

48 |

4 |

18.0 |

72.0 |

| Alternator |

720 |

60 |

1.0 |

60.0 |

| Generated Energy |

- |

- |

- |

180.0 |

|

|

|

|

For each electrical device on board, the daily energy requirement is determined.

Assuming that the power for each device comes from the on-board 12V battery supply,

the power consumption of the device (usually mentioned somewhere on the chassis)

is divided by 12 to obtain the (average) current it draws from the on-board

power supply.

Additionally, the daily time of operation must be estimated.

Consider that electrical devices such as water pumps or refrigerators,

are not continuously active even if they are "switched on"!

So here the effective number of hours the device is really consuming power

must be estimated or experimentally derived by doing long-term

observations.

From this data, the daily required energy [Ah/day] for each device is

obtained by multiplying the current [A] and the daily operation time [h/day].

This is done for each device drawing energy from the on-board power supply

and the sum gives the total energy used daily from this supply.

|

|

The same accounting must be done for the on-board energy sources such

as solar panels or wind generators.

These devices may deliver energy to the on-board power supply and

to the battery system.

But the power output of these generators may vary considerably depending

on the weather conditions (sun, wind, clouds, temperature, ...).

So average values for power and operation time will have to be elaborated

experimentally for this energy account!

It must be taken into account for example that the average power output of

a wind generator will often not exceed 20% of it's peak power!

The same will be true for solar modules, which cannot be optimally

installed on board of a sailing yacht and can be estimated to produce

only about 30%-50% of their nominal power.

The efficiency may decrease even further at higher ambient temperatures

(> 30°).

|

|

Determining the Battery Capacity

For longer journeys without the possibility of recharging the battery

from an external (mainland) power supply, the generated energy should

be higher than the consumed energy.

This requires on-board energy sources such as the alternator

(driven by the in-board engine), solar panels or wind generators!

To provide for some days of battery backup (days with no energy input)

multiply the daily required energy with the number of backup days:

Capacityeff [Ah] = backup-days [days] x daily-required-energy [Ah/day]

This is the required energy that must be made available

for on-board usage.

The installed battery capacity however, must be chosen

about 100% higher:

Capacitybat [Ah] = Capacityeff [Ah] x 2.0

The factor 2.0 accounts for two effects:

only about 60% of the nominal battery capacity should be used regularly

to prevent "over-ageing" of the batteries (providing deep-cycle batteries are used

in the supply system).

due to temperature and ageing effects, the average effective capacity

of a battery system will decrease to about 80% of the original nominal

capacity (as labelled on the batteries).

The energy density of lead-acid batteries is about 35Wh/kg.

For a 12V battery, each Ah of energy results in a battery weight of 0.3kg.

An installation with daily energy requirement of 180Ah and 2 days of

backup will result in 160kg of lead-acid batteries with 540Ah installed

capacity supplying 360Ah effective battery capacity.

Typical cost for a wet-cell lead-acid battery is 1.5 Euro/Ah.

So the total cost for such a battery system will be about

800 Euro.

An equivalent AGM-system will cost about 50% more (2.5 Euro/Ah).

Assembling the required Battery Capacity

The required battery capacity usually can only be obtained by assembling

commercially available batteries in a parallel operation.

The capacity of the parallel battery pack is the sum of the capacities

of the individual batteries.

When connecting batteries in parallel, old and new batteries should never

be mixed and only identical types of battery should be used

(same voltage, same capacity, same type and manufacturer).

Cable lengths should be kept as short possible and the cable size should be

large enough to avoid a measurable voltage drop (less than 0.2V) between the

batteries.

As a simple rule a cable size of 0.05mm2 per effective installed Ah capacity

should be used (e.g. 25mm2 cable size for 540-Ah installed capacity).

Large battery capacities are not very practicable due to the weight

and volume of the required lead-acid batteries.

Therefore another approach would be to rely on the alternator of the

in-board engine to recharge the batteries when no line power from the

mainland is available.

However the loading of lead-acid batteries takes time.

Fast charging with excessive bulk charge currents, will damage

lead-acid batteries.

So if the in-board engine should not run for hours a day just to

recharge the batteries, the only alternative is to reduce the energy

requirements for the autarc periods on sea.

For these periods, the electrical energy supply must be managed in

the same way as water and food supplies are managed.

Obviously, solar panels or wind generators can substantially improve

the energy situation and thus the quality of life on board.

Battery Installation

The in-board boat engine for sailing yachts, normally comes with

a starting battery and corresponding alternator as a complete unit.

The ship builder has - or should have - taken care of special

installation aspects concerning safety, maintenance and the

special maritime environment in which this unit is operating.

The situation for the on-board power supply batteries is usually

different.

Traditionally leisure sailing yachts are equipped with a rather

low battery capacitance for the on-board power supply.

In many cases the battery capacitance will have to be increased

substantially to obtain a "blue-water"-suited sailing vessel.

Since the required battery capacity may finally result in a

large weight of batteries, special attention on the installation

of those batteries should be paid.

Mechanical Installation

Considering the total weight of the required batteries, they should

be installed as low as possible in the vessel and they should

be tightly fixed!

The best position would be in the bilge, just above the keel

provided this is a dry place!

An important aspect is what happens to the batteries if the

vessel is flooding. Safety equipment such as the radio system

should remain operable to broadcast emergency calls.

Also the electric bilge pump should remain under power to work

under such situations.

So the installation of the batteries should be such that the

operation of the on-board power supply system remains fully intact

even in emergency situations.

This can be obtained e.g. by mounting them in an extra compartment,

which should be watertight protecting the system from bilge water

but which must also provide the required amount of ventilation.

Electrical Aspects

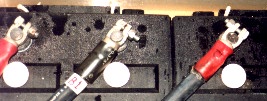

Since a power system normally consists of batteries connected in parallel,

the batteries should be placed close together; if possible in close proximity

to the alternator and battery charger.

In any case, the parallel connection and the connection to alternators should

be done with short and properly sized cables.

The cable size should be at least 0.05sqmm per effective installed Ah.

|

|

Copper cables have a specific resistance of ρ=0.018 Ohm/m/sqmm.

The parasitic resistance of a cable of length L[m] and size d[sqmm] is:

Rcable = ρ * L / d

This resistance will result in a voltage drop over the cable as

soon as electrical current flows through the cable (Vcable =

Rcable * Iload).

This has two consequences:

In low voltage supply networks, the voltage decrease at the load is the

primary design parameter.

Cable sizes should be dimensioned to minimize the voltage drops in the electrical

power system.

Especially the connection between the charging devices and the batteries should

not have a voltage drop of more than 0.1V.

Most regulated battery chargers measure the voltage at their output during charging

and regulate the charging current according to a programmed recharging process.

However, if due to voltage drops between charger and battery, the voltage at the

output of the charger is not identical with the voltage of the battery,

wrong loading currents will be produced, and the battery will not be optimally loaded.

|

The following gives a rough estimation of the expected maximum (average) current

in the power circuit supposing a full charge or discharge in not less than 10 hours:

I10h = effective-installed-battery-capacity [Ah] / 10h

The cable size for the connection between the individual batteries, the alternator

and the battery charger should be dimensioned as follows (provided these

connections are not longer than 2m!):

Acable = 0.50 [mm2/A] * I10h [A]

Consider also that physical connections between cables and device terminals

may also have a substantial contact resistance.

These connections must be made with special connectors designed for feeding

high currents.

One characteristic of such connectors is a large contact area with a relative

crumby metal coating, which combined with a high contact pressure,

assures a uniform current distribution over the physical contact area.

Example:

Installed capacity = 540Ah

Effective capacity = 360Ah

I10h = 54A

Acable = 18.0mm2 (Diametercable = 5.0mm)

|

|

Copper cables have a specific resistance of ρ=0.018 Ohm/m/mm2.

The the resistance of a 10m cable connection with a size of 18.0mm2 is 0.01 Ohm.

Making a closed circuit including the battery charger over this distance

results in a total cable resistance of 0.02 Ohm, yielding a voltage drop

of 0.72V (6%) at 36 Ampere charging current.

This is intolerable, and illustrates the importance of short

and oversized cables for connecting the batteries with the alternator

and the battery charger.

Advanced Battery System for Yachts

The battery system on a typical 40-ft blue-water yacht could consist of the

following components:

a starter battery (80 Ah) for the in-board engine, a heavy-duty service battery (360 Ah) for different "comfort"

applications such as cabin lights, refrigerator, auto pilot and high-power devices such

as inverters and anchor windlass, a safety battery (240 Ah) for safety-related devices such as

radar, HF radio, navigation lights and positioning systems.

The heavy-duty service battery will have the largest capacity and will typically

consist of two identical batteries connected in parallel.

A battery charger with 3 independent outputs will be used for recharging this system.

The negative poles of the batteries are connected to the ground rail through a shunt

(one for each battery system)

Positive poles are NOT connected together. Each battery system operates as an

independent system.

|